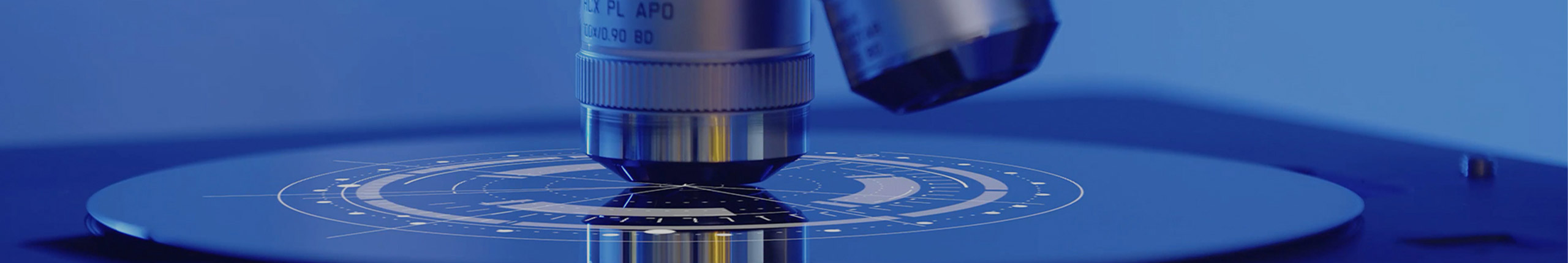

In the chip manufacturing process, key process steps such as plasma etching and Chemical Vapor Deposition (CVD) all require high-precision RF matching networks to ensure the stable generation and precise control of plasma. As chip process nodes continue to shrink, more stringent requirements are imposed on the performance indicators of RF matching networks, including matching accuracy, response speed, and power-carrying capacity.

Application Scenarios

Plasma Etching

RF matching networks ensure the stability of plasma density, enabling nanoscale precision etching to meet the requirements of advanced process nodes.

Chemical Vapor Deposition

Precisely control the deposition rate and film uniformity to ensure the high-quality construction of multi-layer chip structures.

Technical Advantages

The matching accuracy reaches 0.1%, ensuring plasma stability.

Response time is less than 10 microseconds, adapting to rapid process changes.

Supports wide frequency band operation from 13.56MHz to 60MHz

High power handling capability, with a continuous wave output of up to 3000W

Home

Home Product

Product Telephone

Telephone Message

Message